Basic specification:

| X axis travel:400mm | Tool shank type:BT30 | Magazine tool capacity:21tools |

| Y axis travel:400mm | Maximum spindle speeds:12,000rpm | Tool selection method:Absolute address |

| Z axis travel:300mm | Rapid feed rate:50,000mm/min | Tool change time:2.5sec(C To C) |

Processing concept:

Rotate with tilting A-axis index table.

Fixture structure:

Adopt automatic clamping mode.

The workpiece is clamped by oil pressure.

In addition, airtightness detection is used to check whether the workpiece is in place.

Workpiece handling:

The X axis movement of the machine is used as the driving source for workpiece handling.

Upper and lower drive system adopts air cylinder.

The workpiece loading gripper adopts pneumatic expansion gripper

Maximum weight of workpiece to be handled: 10Kg.

Reducing the number of parts not only realizes low cost, but also adds energy-saving countermeasures.

The intermediate transition slide is driven by rod less cylinder, saving

floor space.

The workpiece handling device is set in the machine, which greatly reduces

the floor space.

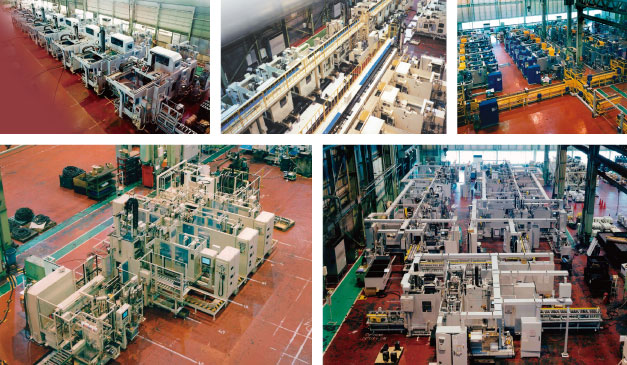

Enshu provides their products and equipment to parts processing industry all over the world for years. Especially in automotive parts processing industry, Enshu’s had plenty of experiences and been admired its highly reliable capability.

Consequently, Enshu were honored by Shanghai GM as Best supplier of the year in 2010.

Cooperating with Enshu Japan, we Enshu (Qingdao) Limited will step up our efforts for better performance in automotive parts processing.

Meanwhile, we’ll keep pursuing the development of our products and technologies to be an essential machine builder in other fields.

Enshu (Qingdao) Limited

West side of Shuangyuan Road, Liuting Street, Chengyang, District, Qingdao, Shangdong, China

TEL: +86-532-66962386

魯公網(wǎng)安備37021402002222號

魯公網(wǎng)安備37021402002222號